Plunger Lift

ULT ADVANTAGES

Low Capital Investment: Not only ULT plunger lift system needs very low capital investment, our plunger lift system can be relocated to other wells easily.

Easy Installation and Maintenance: ULT plunger lift system requires no rig required to install. The downtime for installation is minimal. As the only moving parts in the entire system is the plunger, the required maintenance is also minimal. The cost of maintaining the system is almost negligible.

Production Optimization: ULT plunger lift system is designed to not only effectively prevent paraffin and scale build-up but also stabilize well production and hence extend well production life.

Extremely Environmentally Friendly: ULT plunger lift intelligent controller runs on solar panel and battery with a low power consumption of less than 15 milliwatts.

DESIGN FEATURES

Plunger lift is a common artificial lift technique used for producing low volume, high gas-liquid ratio (GLR) wells. Plunger lift uses the well's own energy to lift the accumulated fluid from the tubing to well surface. The plunger utilizes a mechanical seal between fluid in the tubing and stored gas in the annulus to prevent gas slippage and liquid fallback. ULT plunger lift system reflects the most advanced sensor technologies which have tremendously improved the measurement accuracy. The ULT intelligent controller has five control modes which are field proven to optimize your production.

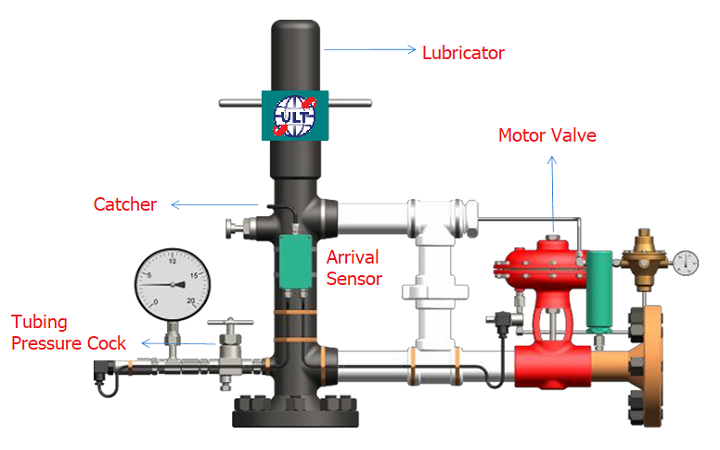

Lubricator: ULT Lubricator top cap has an API ACME#6 thread which provides a much safer connection when high impact plunger is seen at the surface. Also it is equipped with spring housed in the top of the lubricator, which is designed to help cushion the force of the plunger as it arrives into the lubricator. Our lubricator is hydrostatically tested to 5,000 psi per ASTM test standard. It is available is different materials and sizes. The bottom can be threaded or flanged type.

Motor Valve: It is used for opening and closing the flow line and controlled by the membrane valve in the controller.

Casing Pressure Regulator: It is connected between the casing gas feed and the controller and regulates Gas Pressure to approximately 30 psi.

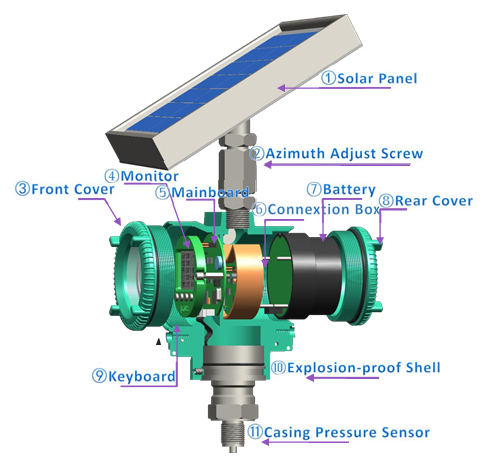

The function of the controller is to open and close the flow line to allow the plunger to fall and rise in the tubing. ULT’s intelligent controller has the following features:

• Measurement accuracy>99% (wellhead temperature range of -40℃~60℃)

• Magnetic field changes and interferences proof

• Integrated design of arrival sensor and pressure sensor.

• Runs on solar panel and battery with a low power consumption of less than 15 milliwatts

• Five control modes (Time Switch Mode, Pressure Switch Mode, Time Optimization Model, Pressure Optimization Model, and Intelligent Mode)

The downhole components include bumper spring, hold-down assembly and plunger. Bumper spring acts as a cushion for the plunger when it falls in the tubing. It also prevents plunger from falling through the end of tubing. Hold-down assembly holds the bumper spring to the tubing. ULT offers three different hold-down methods. A). a cup set in a DH pump seating nipple or a wireline nipple; B).Tubing Stop anchored to the body of tubing by a set of dogs; C).Collar Stop set on the collar between tubing joints.

ULT offers four types of plungers depending on applications. A). spiral plunger; B). tornado plunger; C). padded plunger; and D). brush plunger.

The ULT remote plunger lift control system consists of data transmission system and SCADA platform. Data transmission system is the communication bridge between remote monitoring program and plunger controller.

SCADA platform has five main functions:

1) Remote gas well controls (on/off)

2) Real time data and production curves

3) Operating parameter settings

4). Historical data views

5). Alarms

The system allows an operator to adjust operating parameters real time and manage plunger lift production remotely.